Comparing Various Designs of Galvanometer Scanners for Optimal Efficiency in Labs

Comparing Various Designs of Galvanometer Scanners for Optimal Efficiency in Labs

Blog Article

Key Applications of a Galvanometer Scanner in Different Scientific Research Area

Galvanometer scanners have actually ended up being important to different scientific research areas, using improved accuracy in applications ranging from biomedical imaging to environmental surveillance. Their capability to promote high-resolution imaging methods, such as confocal microscopy, plays a critical function beforehand our understanding of mobile frameworks. In material processing, these gadgets enhance the precision of laser cutting and welding. As we discover the diverse applications of galvanometer scanners, it ends up being apparent that their impact expands much beyond simple technological abilities, elevating concerns concerning their future capacity in emerging study locations.

Biomedical Imaging

In confocal microscopy, galvanometer scanners help with the purchase of images with improved resolution and comparison, permitting researchers to visualize cellular parts in vivo. The capability to swiftly capture several focal aircrafts enhances the three-dimensional restoration of tissues, supplying important insights into their style and function.

In addition, the rapid scanning capacities of galvanometer systems contribute to innovations in dynamic imaging applications, such as keeping an eye on mobile actions to stimuli. Therefore, galvanometer scanners are crucial tools in the area of biomedical imaging, advancing study and medical diagnostics via their precision and efficiency.

Product Processing

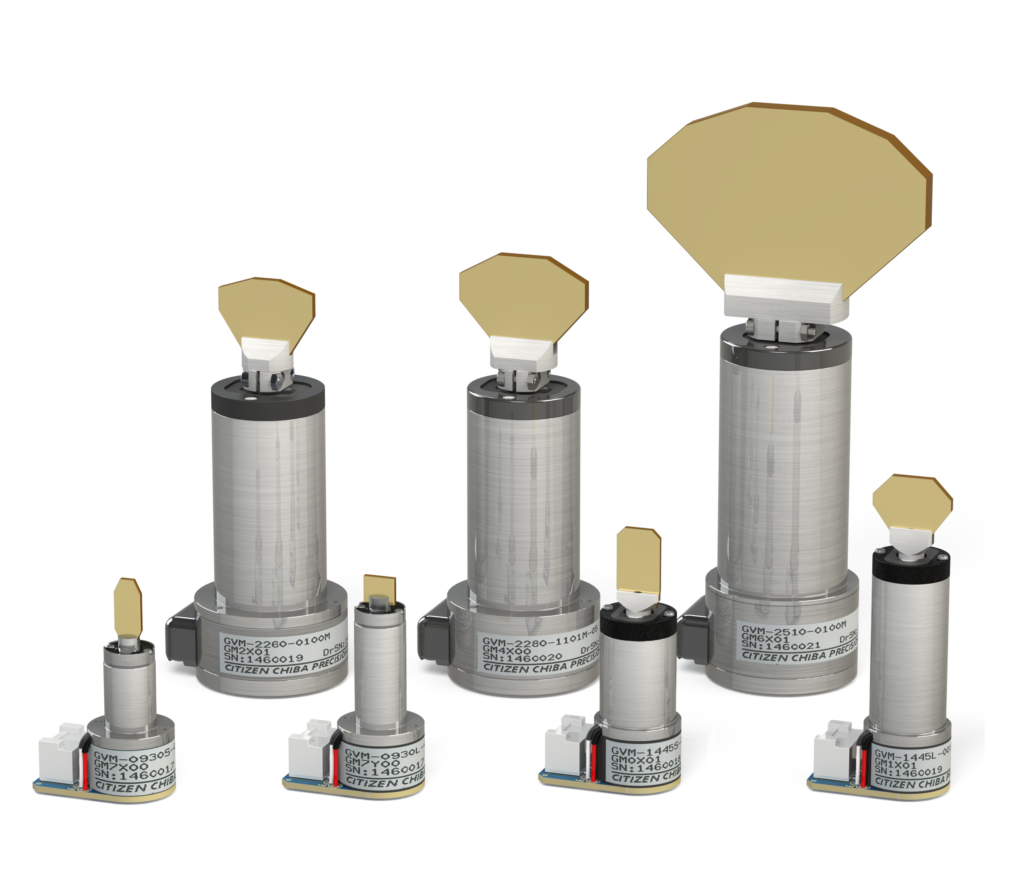

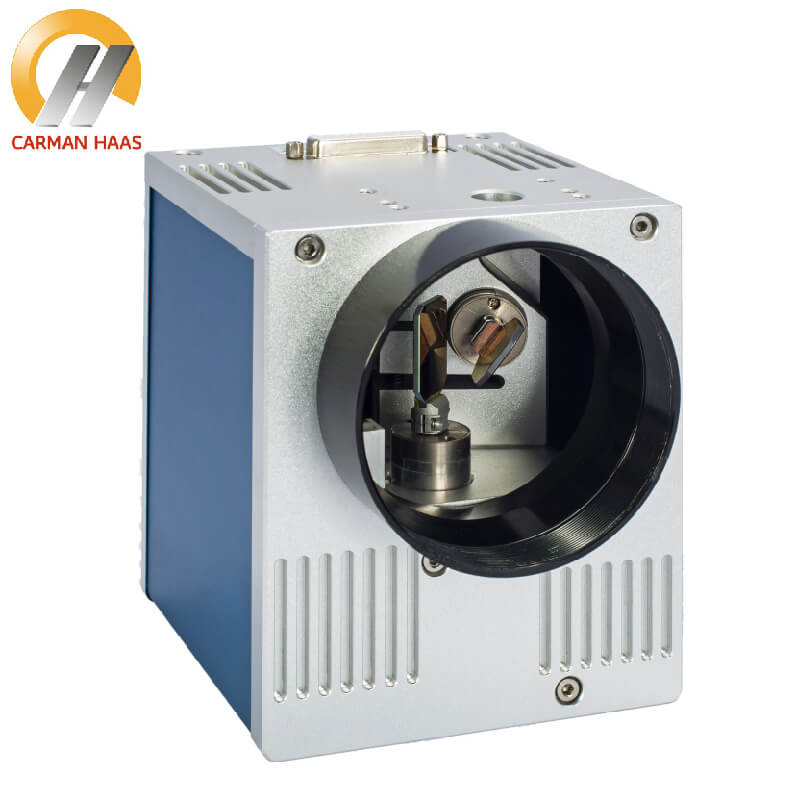

Precision in product handling is critical for achieving premium lead to different industrial applications (galvanometer scanner). Galvanometer scanners play a vital role in boosting this precision by allowing exact and fast motion control throughout the processing of materials such as steels, polymers, and porcelains. These gadgets assist in methods like laser engraving, cutting, and welding, which call for finely-tuned adjustments to ensure optimal results

In laser cutting, for circumstances, galvanometer scanners permit complex designs to be executed with high fidelity, decreasing waste and boosting production performance. The quick activity abilities allow quick modifications in the laser beam of light path, which is important for keeping consistent cutting quality across varying product densities. Likewise, in laser welding applications, the precision offered by galvanometer scanners ensures solid joints with marginal thermal distortion, thus boosting architectural integrity.

In addition, the flexibility of galvanometer scanners to different laser types and wavelengths even more broadens their energy in material handling. Their capability to work in tandem with advanced software program for real-time tracking and control adds an added layer of elegance, enabling makers to achieve precise specs customized to specific applications. Hence, galvanometer scanners are essential beforehand the capacities of product handling modern technologies.

Optical Characterization

In the world of optical characterization, the role of galvanometer scanners ends up being increasingly substantial as they facilitate the evaluation of different optical buildings with high accuracy. These devices make it possible for specific control of laser light beams, enabling scientists to methodically probe materials at multiple angles and regularities. This capability is crucial for characterizing view website the refractive index, absorption coefficient, and scattering buildings of diverse materials.

Galvanometer scanners are especially reliable in visit this website strategies such as optical coherence tomography (OCT) and laser-induced fluorescence (LIF), where quick scanning is critical. By accomplishing high-speed inflection of the laser placement, galvanometer scanners enhance the temporal resolution of these methods, causing boosted imaging and evaluation. In addition, they allow the exploration of complex interactions between light and issue, which is crucial for understanding product habits under various conditions.

Furthermore, the assimilation of galvanometer scanners with spectroscopic strategies broadens their energy, enabling for thorough spooky analysis throughout a large range of wavelengths. This flexibility makes them crucial tools in areas such as materials science, biomedical research study, and nanotechnology, where thorough optical characterization is critical for progressing knowledge and development.

Laser Micromachining

The arrival of laser micromachining has actually changed manufacturing procedures, allowing the creation of detailed frameworks with unequaled accuracy. This technique uses high-intensity laser beam of lights to specifically remove material from a substrate, making it feasible to produce micro-scale parts that are vital in numerous markets. The application of galvanometer scanners in laser micromachining enhances the effectiveness and precision of this process by enabling exact and quick beam positioning.

Galvanometer scanners facilitate the vibrant control of laser light beams, enabling complex patterns to be etched or cut with high fidelity. Their quick action times and high-resolution abilities allow for the control of laser pulses, which is vital for achieving the desired material properties and surface finishes. This modern technology is particularly helpful in fields such as electronics, where the miniaturization of elements is important for performance improvement.

Furthermore, laser micromachining is significantly being employed in the medical field for manufacturing accuracy instruments and implants. The mix of other laser modern technology and galvanometer scanning not only streamlines production workflows however likewise reduces waste and improves overall material usage, making it a sustainable option for modern-day production obstacles.

Environmental Tracking

Environmental monitoring has come to be significantly important in assessing and managing the wellness of ecosystems and urban environments. The integration of galvanometer scanners in this area allows precise, fast, and effective information collection, facilitating far better decision-making procedures. These scanners are proficient at directing laser beams or sensors throughout various terrains, permitting high-resolution mapping of ecological criteria such as air high quality, dirt composition, and water contamination.

In air quality tracking, galvanometer scanners can be utilized to analyze particulate issue and gaseous contaminants, providing real-time data that informs public wellness campaigns. For water quality assessments, these scanners can help in finding pollutants and measuring physical specifications, thereby making sure compliance with environmental regulations. Additionally, in remote sensing applications, galvanometer scanners boost the ability of satellite and drone systems to catch detailed photos and information of substantial areas, determining anthropogenic effects and eco-friendly adjustments.

The adaptability and precision of galvanometer scanners make them important devices in environmental surveillance, adding dramatically to lasting growth initiatives and the security of natural deposits. As the need for efficient ecological management expands, the role of these advanced gadgets will definitely broaden additionally.

Verdict

In recap, galvanometer scanners offer as necessary devices across multiple clinical research study domains. The flexibility and performance of galvanometer scanners proceed to drive improvements in these essential fields.

In laser welding applications, the accuracy offered by galvanometer scanners guarantees solid joints with minimal thermal distortion, thereby boosting structural honesty.

Additionally, the versatility of galvanometer scanners to various laser types and wavelengths further broadens their utility in material handling. By attaining high-speed modulation of the laser position, galvanometer scanners boost the temporal resolution of these techniques, leading to enhanced imaging and analysis. The application of galvanometer scanners in laser micromachining boosts the performance and precision of this procedure by enabling precise and quick beam of light positioning.

Galvanometer scanners facilitate the dynamic control of laser beams, making it possible for complex patterns to be engraved or reduced with high integrity.

Report this page